HR8066 High Precision Static Level for Settlement Monitoring

HR8066 high-precision static force level is applied for high requirement of vertical displacement or settlement monitoring and can accurately detect liquid level changes of 0.01mm. The instrument consists of a series of container with liquid level sensors which are connected together by a fluid-filled connecting tube. The reference container is located at a stable reference point and elevation changes between any one of the containers and the reference container will cause a change in the level within the corresponding container. The elevation change of the measuring point can be obtained by measuring the change of the liquid level.

With RS485 digital signal for easy data collection with high measurement accuracy no drift high reliability and easy installation. The sealed enclosure has good moisture resistance and can work continuously for a long time in a 100% relative humidity environment.

Ⅰ. Overview

The HR8066 high-precision Static level gauge is suitable for vertical displacement or settlement monitoring with high requirements, capable of accurately measuring liquid level changes of 0.01mm. The instrument consists of a series of containers equipped with liquid level sensors, which are interconnected by a liquid-filled communicating tube.

Working Principle:

The reference container is located on a stable reference point, and any elevation change between any container and the reference container will cause a corresponding liquid level change in the container. By measuring the liquid level change, the elevation change at the measuring point can be obtained.

The instrument features an RS485 digital signal for convenient data acquisition. It boasts high measurement accuracy, no drift, strong reliability, and easy installation. The sealed casing provides excellent moisture resistance, allowing for long-term continuous operation in an environment with 100% relative humidity.

Ⅱ. Technical Specifications

Standard Range: 1000mm

Accuracy: <±0.5mm

Resolution: 0.01mm

Annual Stability: <±0.5mm

Output Signal: RS485

Operating Temperature Range: -20~85°C

Temperature Compensation Range: -20~60°C

Overload Capacity: 200% F•S

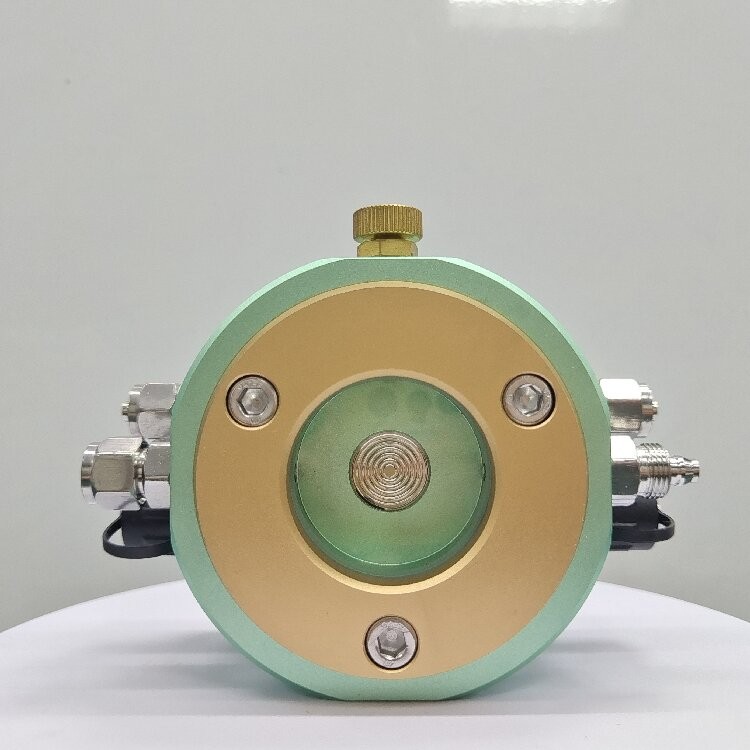

Case Material: Aluminum Alloy

Electrical Connection: Waterproof Four-Pin Connector

Protection Grade: IP67

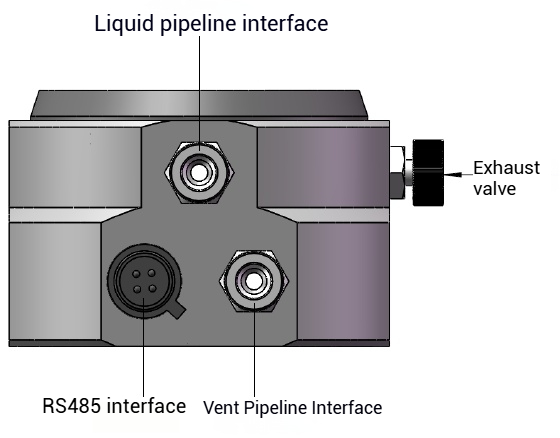

Installation Method: Fix vertically with the exhaust valve upwards

Wiring Method for Output Signal (RS485):

Red - Power +

Yellow - Power -

Blue - RS485-A

Green - RS485-B

Ⅲ. Communication Interface

The instrument adopts an industrial-grade RS485 communication interface, operating in a half-duplex master-slave mode with a transmission distance up to 1200 meters.

Serial Port Number: The serial port number for the communication serial port, default to COM1. It should be set according to the actual serial port number connected on the computer during use.

Baud Rate: 9600bps;

Parity: None.

Stop Bits: 1 bit.

Data Bits: Fixed at 8 bits.

The supported communication protocol is MODBUS-RTU. After connecting the external power supply, the instrument can be operated through computer software or an MODBUS master (such as an RTU device) by sending commands, such as collecting pressure and temperature values.

Ⅳ. Communication Protocol

Function Code: 0x04 for reading registers.

Starting Address for Input Registers: 0x0000;

To read:

Liquid Level Value: 01 04 00 00 00 02 71 CB

Temperature Value: 01 04 00 02 00 02 D0 0B

Liquid Level + Temperature Value: 01 04 00 00 00 04 F1 C9

Both pressure and temperature values are represented using IEEE754 standard four-byte single-precision floating-point numbers.

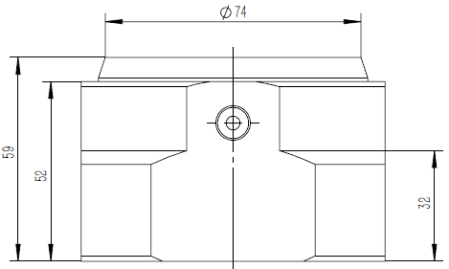

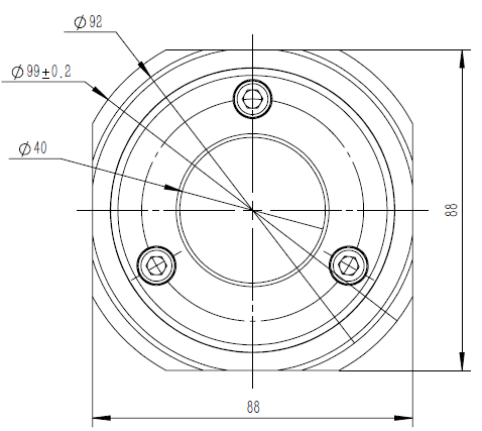

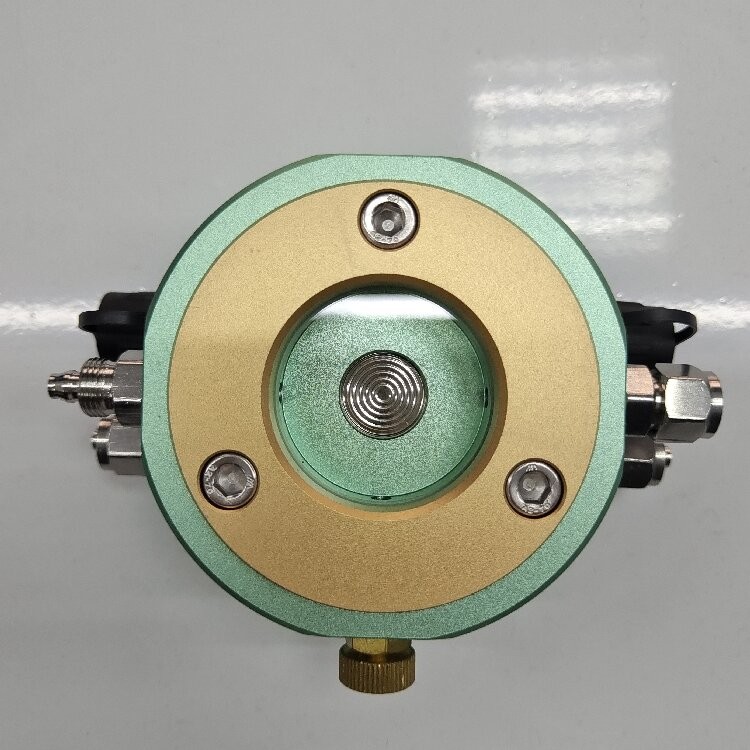

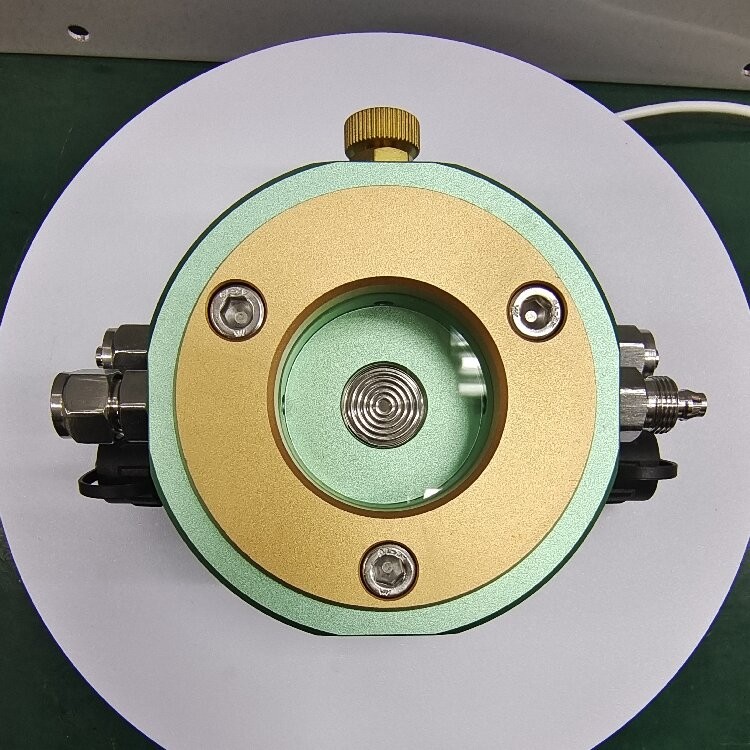

Ⅴ. Dimensions

Ⅵ. Cable and Piping Connection Locations

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact:Roxy Deng

Phone:+8617794001501

Tel:+8617794001501

Email:roxy@besteetech.com

Add:Weibin District, Baoji, Shaanxi Province, China

Roxy Deng

Roxy Deng Roxy Deng

Roxy Deng