Solutions-Flow Transmitter

How to Reasonably and Correctly Select the Type and Model of Water Level Gauges

Water level gauges are instruments that can automatically measure and record the water levels of rivers, lakes, irrigation canals, and other water bodies. In practical applications, the choice of water level gauges varies depending on the scale and form of the project, development needs, and the location of application. With the development of society and the progress of the times, as well as the pursuit of higher engineering quality, more accurate signal acquisition, enhanced practical performance of products, and the need for less investment, land usage, and simpler construction, water level gauges that meet these criteria will increasingly be selected for water conservancy projects. The main considerations for selection include:

1. The measurement object, such as the physical and chemical properties of the measured medium, as well as the working pressure, temperature, installation conditions, and the speed of liquid level changes.

2. Measurement and control requirements, such as measurement range, measurement (or control) accuracy, interfaces with computers, safety and corrosion protection, reliability, and ease of construction.

3. Radar water level gauges, pressure water level gauges, bubble water level gauges, float water level gauges, ultrasonic water level gauges, and electronic water level rulers are six commonly used types of water level gauges. This article summarizes the selection of water level gauges.

I. Radar Water Level Gauge

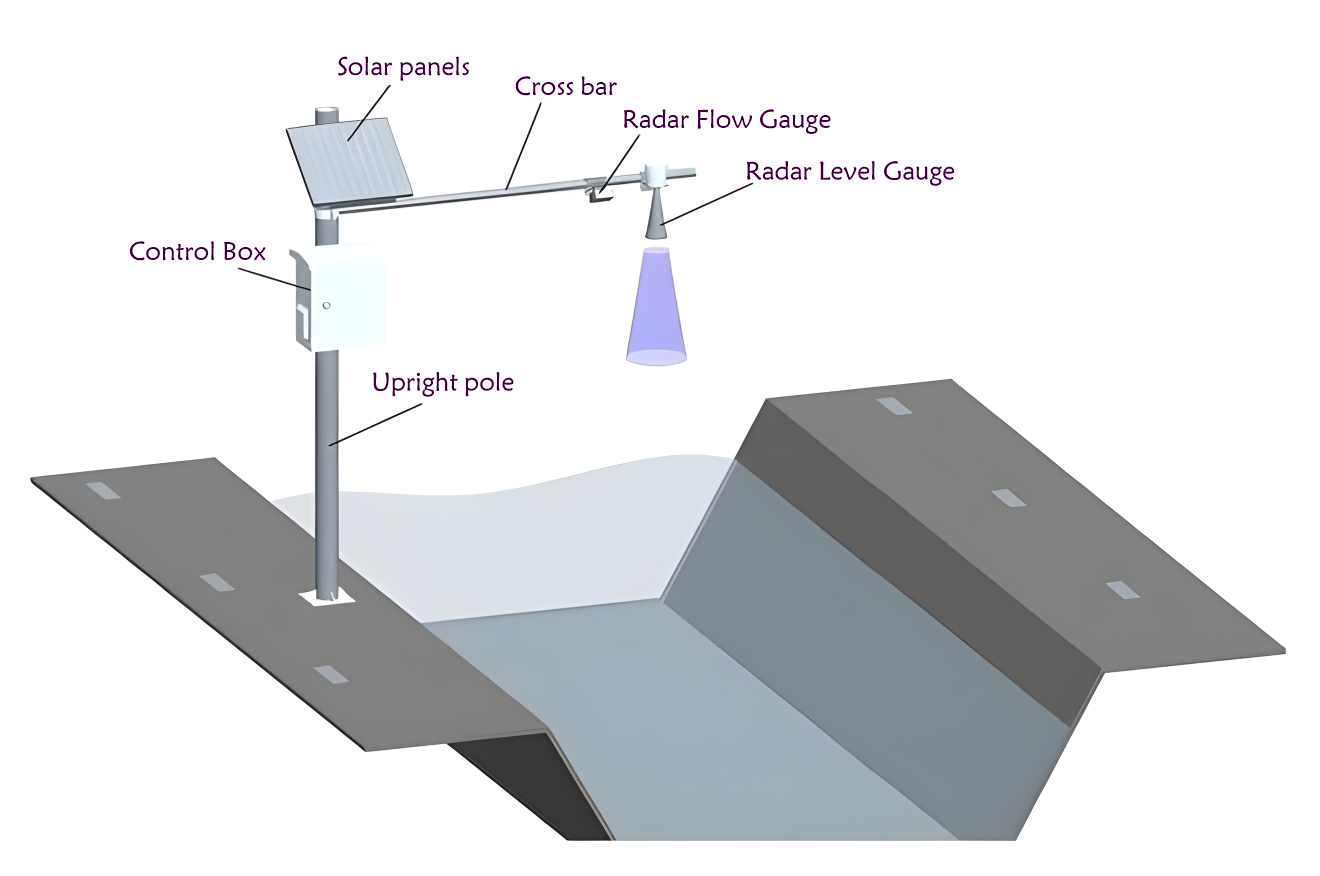

A radar water level gauge, also known as a water level radar, is an electronic device that uses electromagnetic waves to detect targets. It was developed primarily for water conservancy monitoring, sewage treatment, and flood warning. Its main measurement principle involves emitting radar pulses from the radar water level sensor antenna, with the antenna receiving the pulses reflected back from the water surface and recording the time T. Since the propagation speed C of electromagnetic waves is a constant, the distance D to the water surface can be calculated.

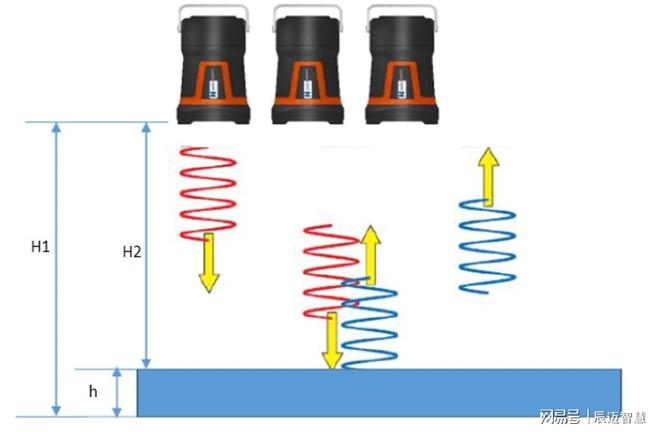

As shown in the diagram, the radar water level gauge calculates the distance H2 = c*Δt/2 between the radar water level gauge and the liquid surface by measuring the emission and reception time difference Δt of electromagnetic waves, and the output water level value h = H1 - H2. H1 is the height from the bottom of the canal to the water level gauge, also known as the installation height of the radar water level gauge.

Scope of application and characteristics:

1. High measurement accuracy (millimeter-level) and large measurement range (up to 70 meters or more).

2. Only the probe needs to be placed above the water level, significantly reducing civil construction investment.

3. Non-contact measurement, not limited by water quality environments, and does not disrupt water flow structures.

4. Unaffected by environmental factors such as temperature, humidity, wind speed, and rainfall, providing stable and reliable data.

5. Signal output modes: RS485, RS232, 4~20mA analog.

6. Suitable for water level monitoring projects in open water bodies such as reservoirs, lakes, rivers, and canals, as well as in narrow spaces such as manholes and tanks, and can be applied in high-temperature, high-pressure, and highly corrosive installation environments.

Disadvantages:

1. In cold environments, the antenna is prone to crystallization and icing, which can cause data errors and require periodic handling.

2. The installation environment should avoid obstacles or floating objects, as the radar waves may mistake them for the water surface, causing inaccurate data.

3. Installation must be perpendicular to the water surface, and the radar waves must fully cover the water surface.

II. Pressure Water Level Gauge

The pressure water level gauge uses the principle of static pressure measurement. When the water level gauge is lowered into a certain depth of the measured liquid, the pressure sensor's liquid-facing surface receives pressure, which is introduced into the sensor's positive pressure chamber through a stainless steel gas conduit. Meanwhile, the atmospheric pressure Po on the liquid surface is connected to the sensor's negative pressure chamber to offset the Po on the sensor's back side, so that the pressure measured by the sensor is ρ·g·H. By measuring the pressure P, the liquid level depth can be obtained.

Scope of application and characteristics:

1. High measurement accuracy (millimeter-level) and large measurement range (up to 300m or more, customizable range).

2. Differential pressure liquid level measurement has no mechanical wear, is reliable in operation, stable in quality, and has a long lifespan.

3. Easy to install, with the sensor directly placed in the water, saving on civil construction costs.

4. Output signals: RS485, RS232, 4-20mA analog.

5. Relatively low equipment costs.

6. Widely applicable for monitoring occasions such as groundwater observation wells, water source wells, geothermal wells, ponds, canals, reservoirs, and road ponding.

Disadvantages:

1. Temperature and medium density affect accuracy.

2. Pressure probes can be clogged by silt and debris, affecting accuracy.

3. Immersion measurement is affected by water quality, and cannot be used for corrosive water.

4. Pressure-resistive sensors may drift over time and with temperature changes, requiring regular calibration.

III. Bubble Water Level Gauge

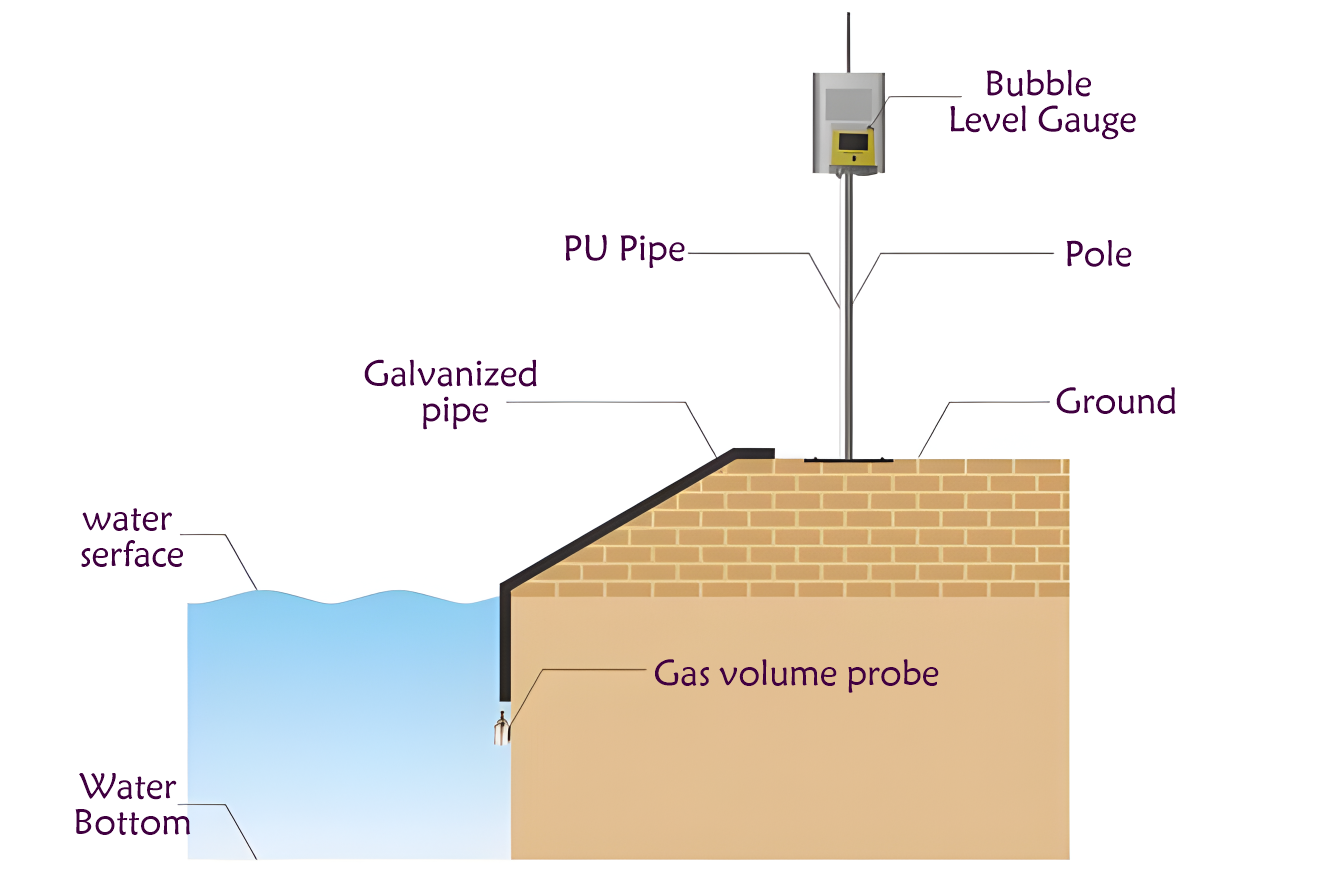

The bubble water level gauge is a new generation of high-precision, intelligent bubble water level gauge independently developed and produced by our company, complying with the GB/T11828 standard. It features easy installation, high accuracy, high reliability, non-contact measurement, high compatibility, and multiple communication interfaces. This product is suitable for China's water quality and conditions, particularly for water level monitoring of small and medium-sized rivers, water levels of power plant surge shafts, upstream and downstream water levels of dams, ocean and groundwater levels, as well as water levels and liquid levels in chemical plants, coal mines, sewage treatment plants, and water treatment plants. It is applicable in areas where it is inconvenient or expensive to build monitoring wells. The product has obtained production and measurement licenses.

A tube with a pressure sensor and air source at the upper end is inserted into the water, and a small amount of air or inert gas is constantly introduced into the tube. The pressure sensor measures the gas pressure in the tube, which is proportional to the water head above the end of the tube, and converts it into a water level through a recording system.

Scope of application and characteristics:

High measurement accuracy (millimeter-level) and large measurement range (up to 70m or more), maintenance-free, vibration-resistant, and long lifespan.

Easy installation, simple operation, and flexible networking. The instrument only requires the air conduit and air chamber to be placed in the water, eliminating the need for a monitoring well and saving on civil construction investment.

The device has no "electrical" connection with the measured water body, only a single air tube entering the water, avoiding many interferences and impacts, and ensuring stable and reliable data.

Signal output modes: RS485, RS232, 4-20mA.

Particularly suitable for flowing water bodies, large, medium, and small rivers, reservoirs, or industrial wastewater with heavy pollution and strong corrosion.

Disadvantages:

Silt and debris at the bottom can clog the probe, affecting accuracy.

Due to low power consumption, the air pump may lack sufficient pumping force and cannot be used in environments with poor conditions (e.g., lots of silt and debris).

IV. Float Water Level Gauge

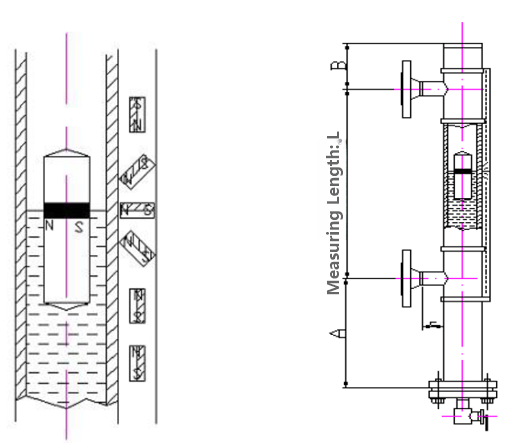

The float water level sensor is a digital sensor integrating mechanical and electrical technologies. It converts the angular displacement of the output shaft into a corresponding digital value to measure the height of the measured liquid level with high accuracy and confirm the position. It has a power-off memory function.

Its working principle is as follows: The water level sensor's measuring wheel is installed on the encoder's input shaft, with a steel wire rope connecting a float on one end and a counterweight on the other, winding around the measuring wheel. When the liquid level changes, the float rises or falls accordingly, causing the steel wire rope to drive the measuring wheel to rotate, and the encoder outputs the corresponding real-time water level value. The sensor has a reasonable structure, strong anti-interference ability, high resolution, large measurement range, long lifespan, and a signal memory function after power failure. It can be used for long-term liquid level measurement and ensures stable and reliable performance. It is widely applicable for water level measurement of rivers, lakes, reservoirs, navigation locks, hydropower stations, hydrological stations, water plants, as well as surface or groundwater in petrochemical industries.

The float senses the water level. When the water level remains unchanged, the forces on both sides of the float and the counterweight are balanced. When the water level rises, the float generates upward buoyancy, causing the counterweight to pull the suspension cable and drive the water level wheel to rotate clockwise, increasing the display reading of the water level encoder. When the water level drops, the float sinks and pulls the suspension cable to drive the water level wheel to rotate counterclockwise, decreasing the display reading of the water level encoder.

1. Relatively simple principle and relatively small error.

2. Centimeter-level accuracy with a measurement range of up to 40m or more.

3. Output signals: 4-20mA/RS485.

4. Suitable for low-sediment reservoirs, lakes, rivers, and canals with stable bank slopes and minor riverbed siltation.

Disadvantages:

1. Must be installed within a water level well;

2. The well logging pipe must remain straight and cannot be bent, making equipment installation and construction challenging.

V. Ultrasonic Level Gauge

The working principle of an ultrasonic level gauge is that a transducer (probe) emits high-frequency ultrasonic pulses, which are reflected by the surface of the measured medium and partially received by the same transducer. The reflected waves are converted into electrical signals.

Scope of Application and Characteristics:

1. Non-contact measurement, requiring no direct contact with the medium;

2. High measurement accuracy (millimeter-level) and large measuring range (above 30m);

3. Capable of measuring a wide range of liquids, bulk materials, and powder levels;

4. Simple and convenient installation without the need for safety protection;

5. Output signals: 4-20mA/RS485/RS232;

6. Suitable for water level measurement in rivers, lakes, reservoirs, canals, navigation locks, and various hydraulic structures.

Disadvantages:

1. Lower accuracy with a blind zone in measurement;

2. Not suitable for measurement sites with heavy fog or dust;

3. Measurement accuracy is susceptible to temperature, humidity, and wind waves;

4. In the presence of bubbles, the measured value may deviate significantly from the actual liquid level.

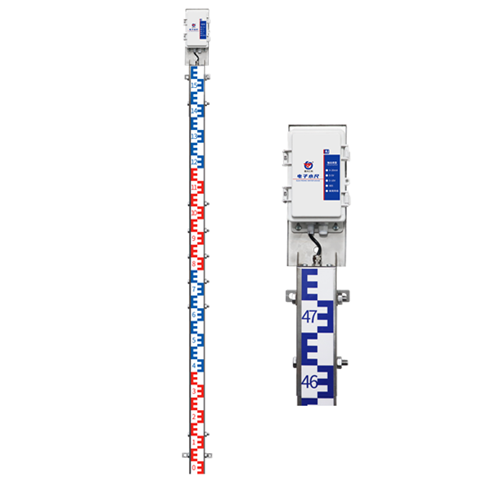

VI. Electronic Water Gauge

The electronic water gauge is a new generation of digital sensors that utilize the principle of water's weak conductivity to measure water levels at electrodes and obtain data. Errors are not influenced by environmental factors but only depend on electrode spacing. It can continuously and automatically detect water levels over an extended period and is suitable for water level monitoring in hydraulic engineering projects such as rivers, lakes, reservoirs, hydropower stations, irrigation areas, and water conveyance systems, as well as municipal engineering projects like tap water supply, urban sewage treatment, and urban road ponding.

Measurement Principle:

Utilizing the principle of water's weak conductivity, when water reaches a certain position on the water gauge, the corresponding circuit scans the highest contact point in contact with water to determine the water level.

Scope of Application and Characteristics:

1. Unaffected by environmental factors;

2. High measurement accuracy, stability, reliability, and ease of use;

3. Output signals: RS485/4-20mA;

4. Commonly used for liquid level monitoring in municipal engineering projects such as tap water supply, urban sewage treatment, and urban road ponding.

Disadvantages:

1. Limited measuring range;

2. Not suitable for deeper reservoirs and lakes, with significant limitations.

RELATED NEWS

- Technical Introduction of Reverse Flushing Flow Meter 2025-06-12

- Liquid Level Switch, Level Meter And Liquid Level Transmitter 2025-05-22

- Troubleshooting Methods for Electromagnetic Flowmeters 2025-04-28

- Understanding the Basics of Groundwater Quality Monitoring Data 2025-04-15

- Capacitive Level Gauges vs. Self-Powered Level Gauges 2025-03-19

CATEGORIES

LATEST NEWS

CONTACT US

Contact:Roxy Deng

Phone:+8617794001501

Tel:+8617794001501

Email:roxy@besteetech.com

Add:Weibin District, Baoji, Shaanxi Province, China

Roxy Deng

Roxy Deng Roxy Deng

Roxy Deng