Product Solutions-Torque Tools

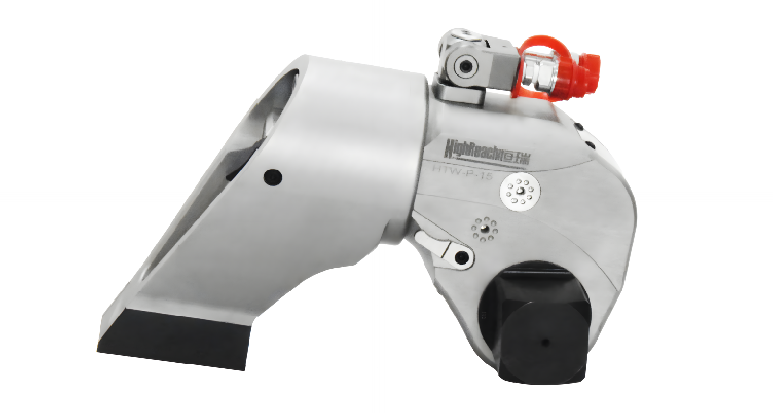

How to Maintain Hydraulic Torque Wrenches?

In today's industrial production, hydraulic torque wrenches, as one of the hydraulic machines, are extensively used. Their emergence has greatly enhanced many people's work efficiency and reduced manual labor. When operating hydraulic wrenches, how can we maintain them to effectively extend their service life?

Maintenance Tips During the Operation of Hydraulic Wrenches

1.Select Different Sleeves Based on Usage

Users of hydraulic wrenches work in various environments. During actual use, it is essential to determine the sleeve to be used according to the size of the nut to be pre-tightened. Failing to change the sleeve based on actual conditions will not only prevent normal use but may also damage the hydraulic wrench itself.

2.Carefully Read the Instructions Before Operating the Hydraulic Wrench

Regardless of whether you have used a hydraulic wrench before, always carefully read the operation manual. Different models of hydraulic wrenches have different operating methods, and it is crucial to follow the instructions.

3.Hydraulic Oil Requirements for Hydraulic Wrenches

When operating the hydraulic wrench, always add hydraulic oil as specified in the manual and do not use any other liquid as a substitute. Before adding hydraulic oil, check its cleanliness. Impurities should not be present as they can damage the hydraulic wrench.

4.Avoid Collisions During Operation or Transportation of Hydraulic Wrenches

As an important tool in the industry, users must handle hydraulic wrenches gently during operation or transportation to avoid collisions and protect the wrench as much as possible.

Only by following the above steps during the operation of hydraulic wrenches can they be properly maintained. If you encounter any uncertainties while using a hydraulic wrench, please feel free to contact me, and I will provide detailed answers for you!

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact:Roxy Deng

Phone:+8617794001501

Tel:+8617794001501

Email:527924493@qq.com

Add:Weibin District, Baoji, Shaanxi Province, China

Roxy Deng

Roxy Deng Roxy Deng

Roxy Deng