Solutions-Flow Transmitter

Radar Level Transmitter Air Purge Technology Analysis

I. Air Purge Technology Principle

Air purge technology is widely used in industrial sectors that require level measurements, especially in materials prone to condensation, adhesion, or clumping. Common industries include cement, sugar, biscuits, fertilizers, plastic granules, among others.

A radar level transmitter is a non-contact level measurement instrument that uses microwave signals to measure the distance to materials. In practical applications, the surface of materials may be affected by contaminants, leading to inaccurate measurements. To address this issue, radar level transmitters employ air purge technology.

Air purge technology involves the injection of a stream of air onto the surface of materials during the measurement process to remove contaminants before taking measurements. This technology primarily includes static pressure purging and dynamic pressure purging methods. Static pressure purging compresses air to a certain pressure and sprays it onto the material surface to remove contaminants, while dynamic pressure purging uses airflow generated by the material's movement to purge the material surface. Each method has its own advantages and disadvantages, and the choice should be based on the specific situation.

II. Air Purge Principle of Radar Level Transmitter

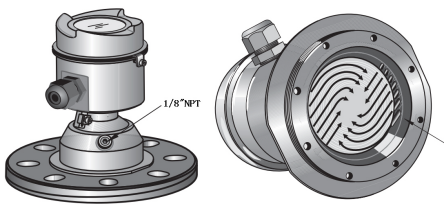

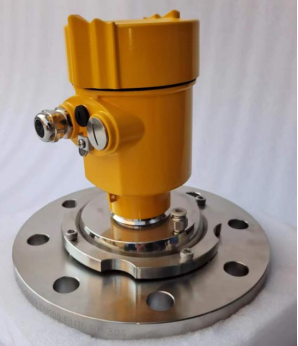

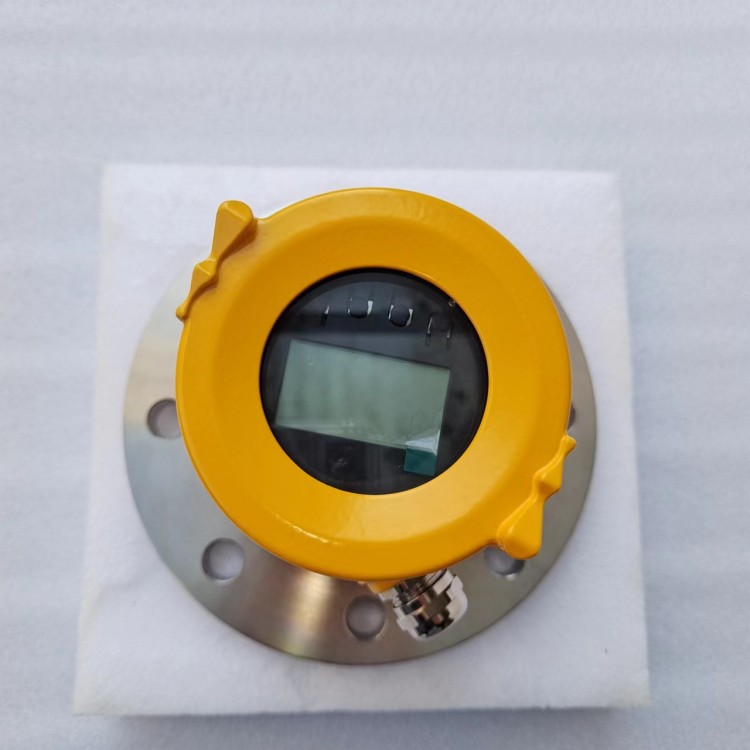

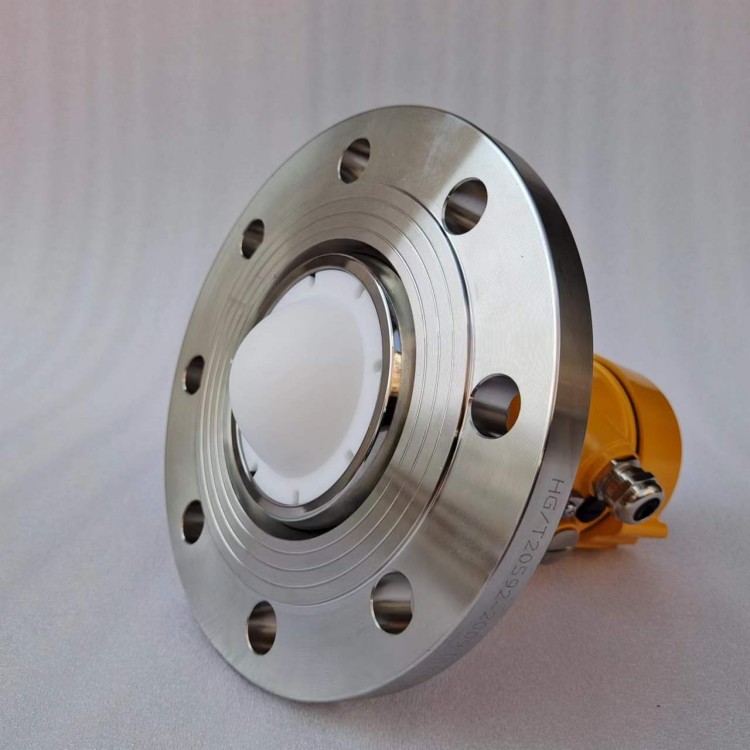

Above the flange of the radar level transmitter, there is an air purge inlet with NPT internal threads (the size depends on the specific conditions).

On the outer side of the lens antenna, there are outlets for the air purge flow, which can generate a strong vortex to quickly clean the lens surface. The air purge can remove contaminants or moisture adhering to the lens surface. Short-duration high-pressure air purging is more effective than continuous low-pressure purging. Additionally, some solid particles are abrasive, and continuous low-pressure purging can damage the lens surface.

Therefore, based on different operational requirements, it is recommended to use periodic short-duration high-pressure purging, typically for a few seconds per hour, with a purging pressure of 90-110 psi. Refer to the accompanying diagram for the location of the air purge port and the vortex effect.

Ⅲ. Advantages of Air Purge Technology

Radar level transmitters utilizing air purge technology offer the following advantages:

Improved Measurement Accuracy

Air purge technology can remove contaminants from the material surface, reducing measurement errors caused by them and enhancing measurement accuracy.

Enhanced Durability

By clearing contaminants, the buildup of materials on the probe can be avoided, reducing probe wear and extending its lifespan.

Suitability for Various Materials

Air purge technology is applicable to a wide range of materials, unaffected by the surface properties of the materials, making it highly versatile.

Ⅳ. Limitations and Development Trends of Air Purge Technology

While air purge technology plays a positive role in addressing the impact of material surface contaminants on measurement accuracy, it also has certain limitations. For example, the air purge process can introduce additional measurement errors, air purge nozzles require cleaning after prolonged use, and air purging can increase equipment costs. Therefore, air purge technology still needs further improvement and optimization.

In the future, with the continuous advancement of industrial technology, air purge technology will become more intelligent and automated. It will continually enhance measurement accuracy and equipment stability, providing more precise and reliable level measurement solutions for industrial applications.

5. Does a radar level transmitter need to have a purging function?

Whether a radar level transmitter needs a purging function depends on the application environment and the characteristics of the material being measured.

In certain operating conditions, especially when the measurement environment contains a significant amount of dust, steam, or materials prone to adhesion, a radar level transmitter with a purging function is particularly important. The purging function involves blowing air or inert gas into the antenna area to prevent material from adhering to the antenna, thereby ensuring measurement accuracy and equipment reliability.

Below are some scenarios where a radar level transmitter with a purging function is suitable.

High dust environments:

Such as storage silos for materials like coal, cement, powdered chemicals, where dust concentrations are high, making it easy for dust to cover the radar antenna, affecting measurement signals.

Viscous or easily clumping materials:

Some materials tend to adhere to the antenna, affecting the emission and reception of radar waves. Purging can reduce the occurrence of this issue.

Steam or humid environments:

In environments where steam or condensation occurs, water droplets or moisture may adhere to the antenna. Purging helps keep the antenna dry, ensuring measurement accuracy.

However, not all applications require a purging function. For instance, if the measurement environment is relatively clean or the material does not easily adhere, a radar level transmitter without a purging function may be sufficient. Additionally, there are designs like lens antenna radar level transmitters that reduce dust adhesion through specially designed antennas and may work effectively without the need for additional purging functions.

In practical applications, it is important to choose the appropriate purging method and radar level transmitter model based on individual needs and actual conditions to achieve the best measurement results.

If you wish to know more about the Radar level transmitter with omnidirectional flange, pls click here to scan:

https://besteetech.com/product/80-GHz-Radar-Level-Transmitter-with-Omnidirectioanl-Flanges-e.html

RELATED NEWS

- Technical Introduction of Reverse Flushing Flow Meter 2025-06-12

- Liquid Level Switch, Level Meter And Liquid Level Transmitter 2025-05-22

- Troubleshooting Methods for Electromagnetic Flowmeters 2025-04-28

- Understanding the Basics of Groundwater Quality Monitoring Data 2025-04-15

- Capacitive Level Gauges vs. Self-Powered Level Gauges 2025-03-19

CATEGORIES

LATEST NEWS

CONTACT US

Contact:Roxy Deng

Phone:+8617794001501

Tel:+8617794001501

Email:roxy@besteetech.com

Add:Weibin District, Baoji, Shaanxi Province, China

Roxy Deng

Roxy Deng Roxy Deng

Roxy Deng